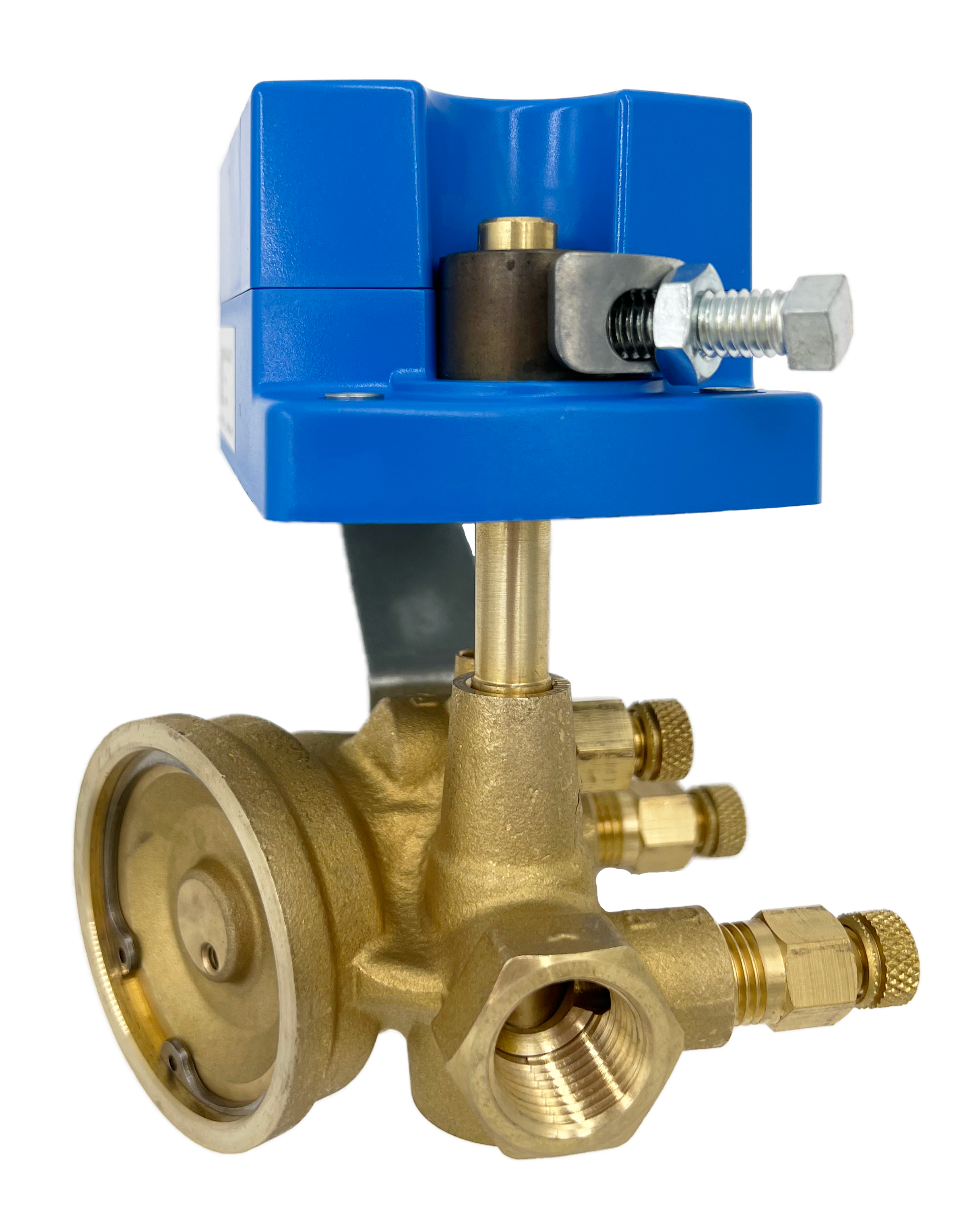

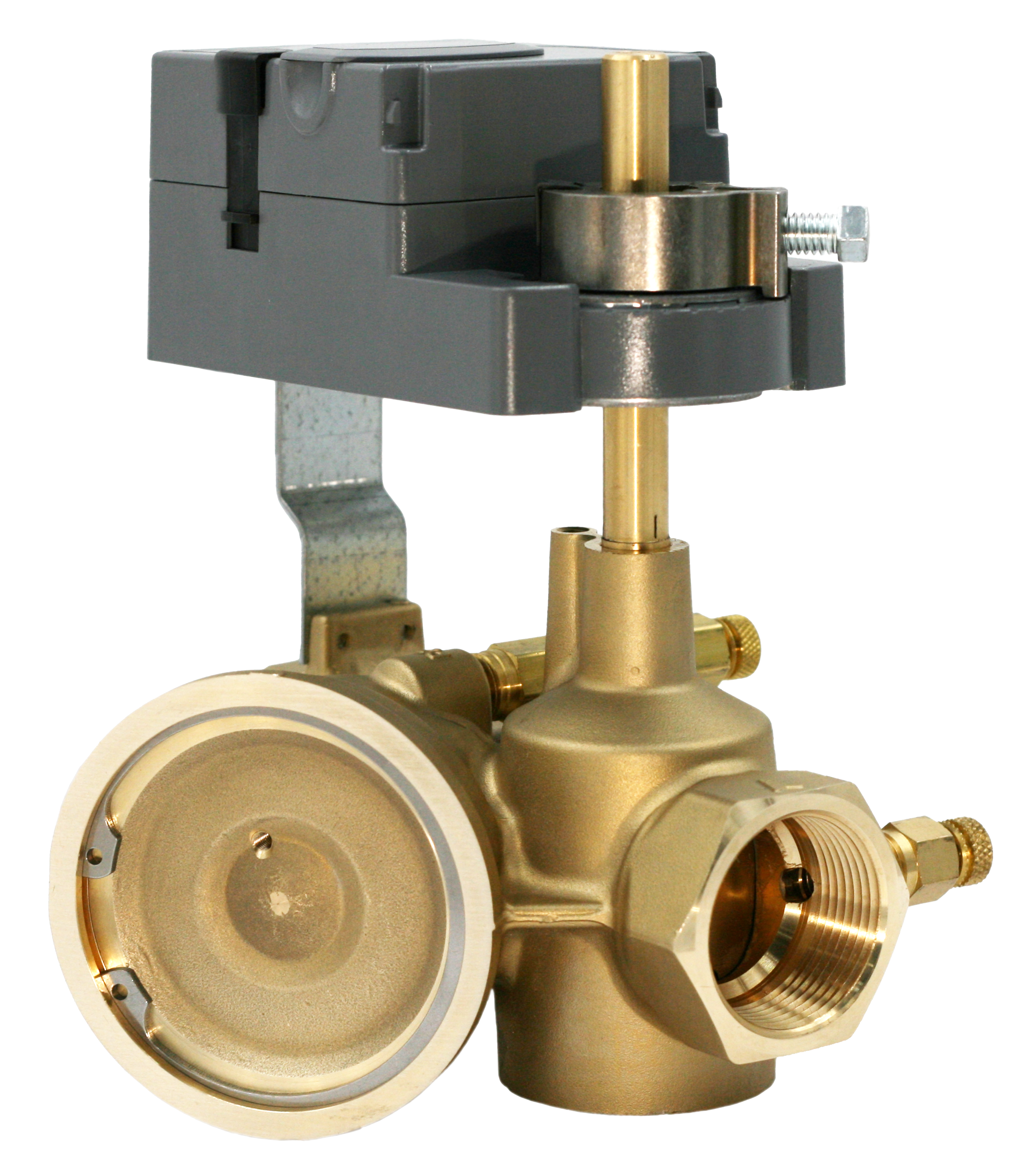

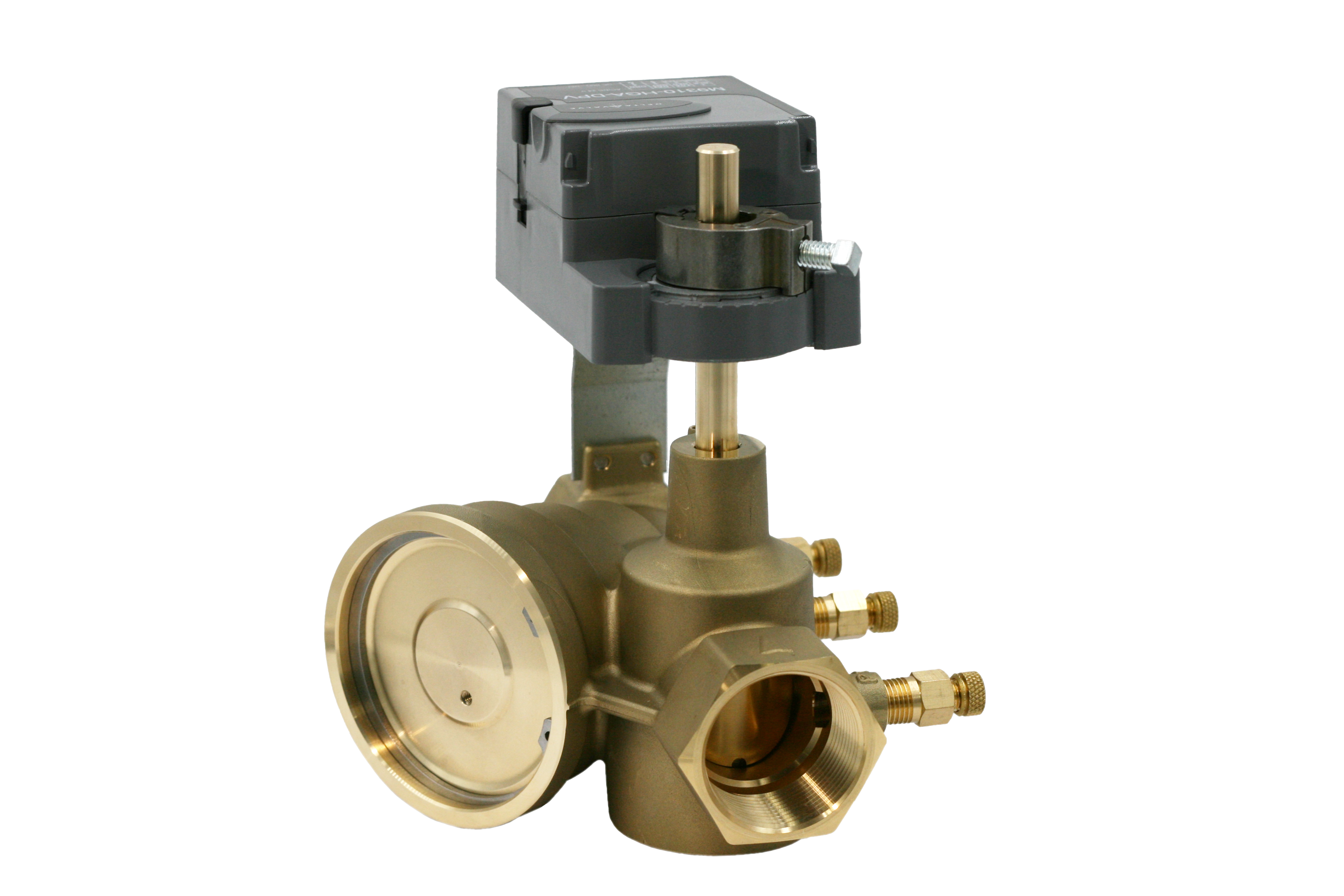

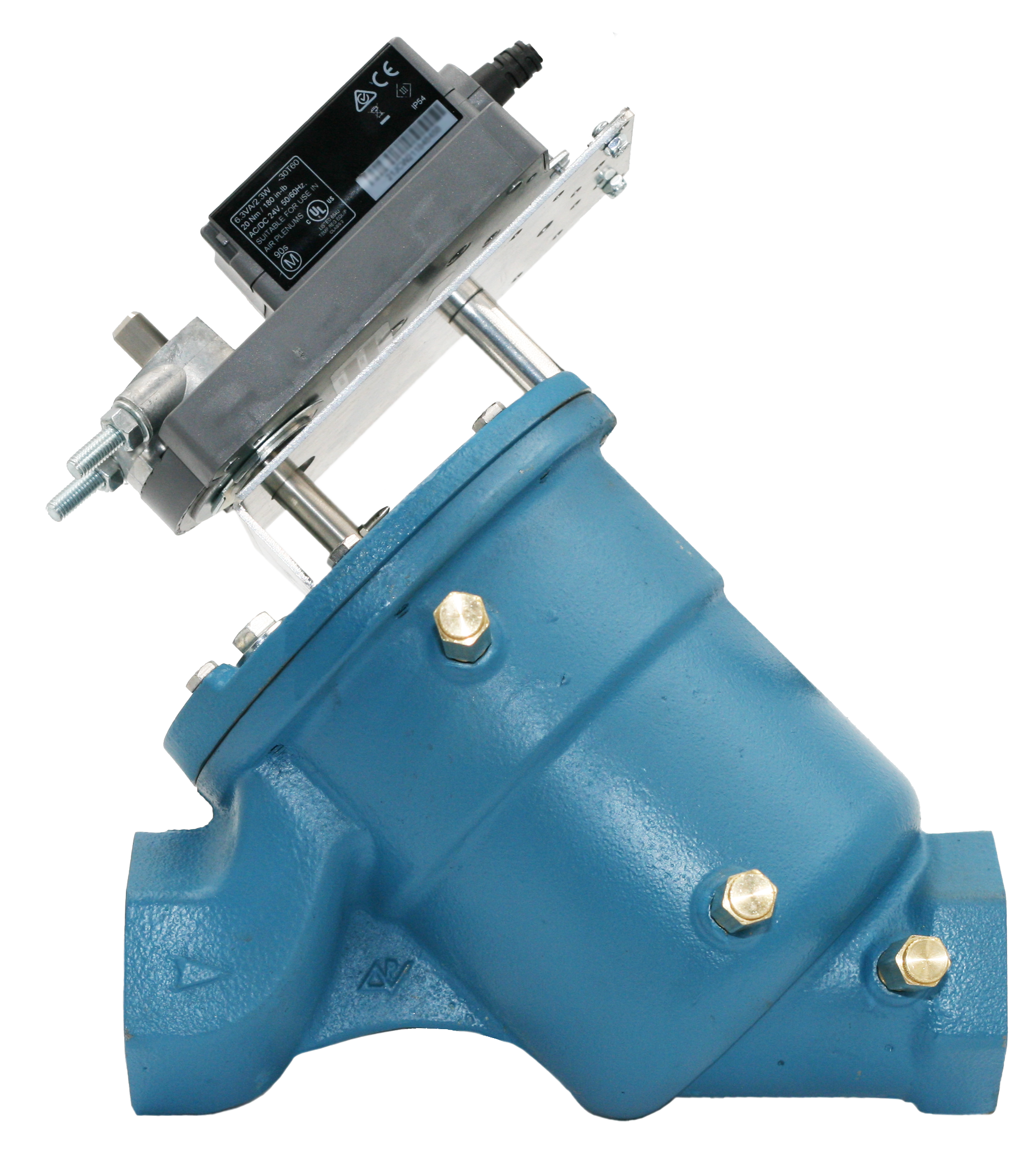

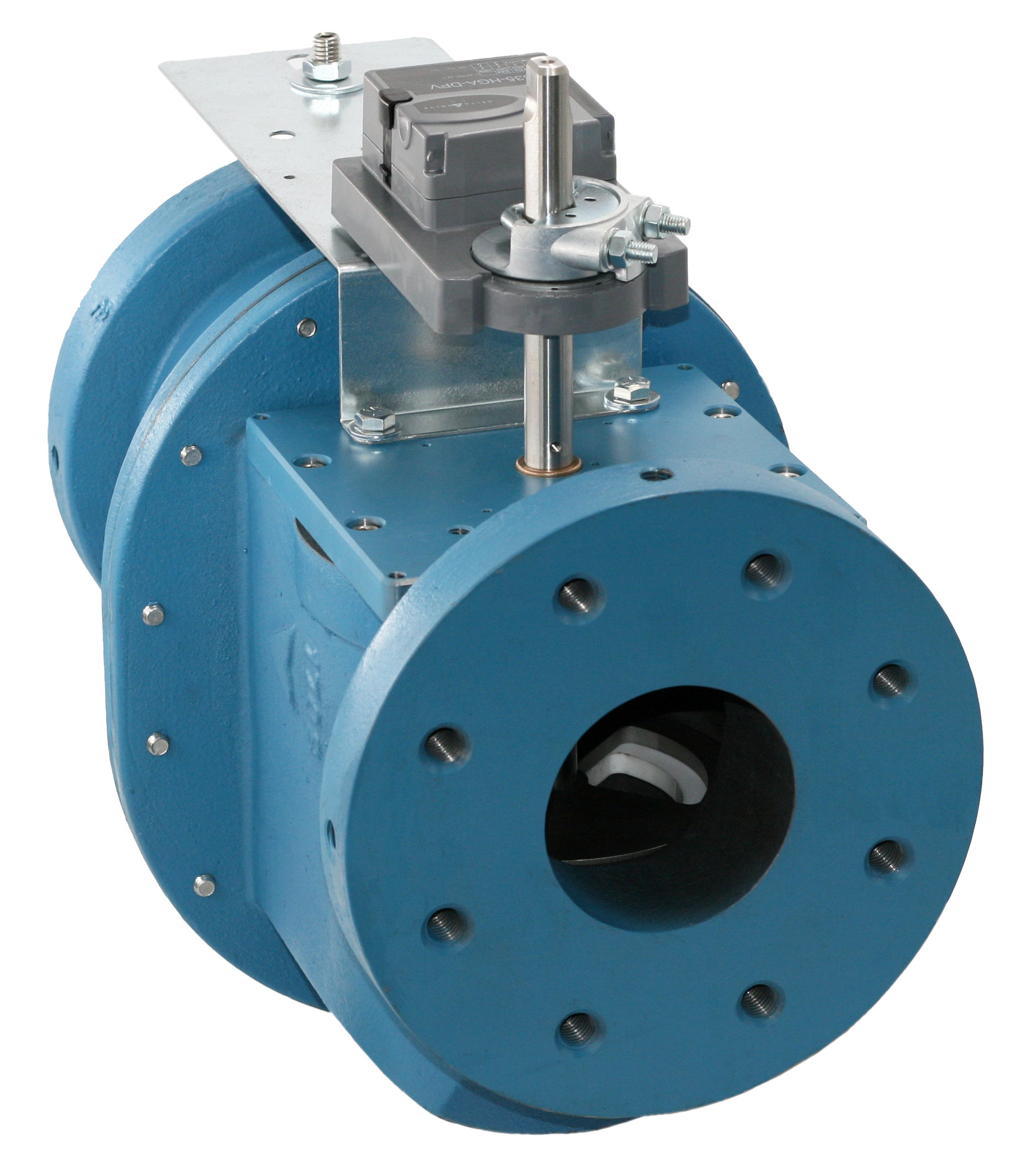

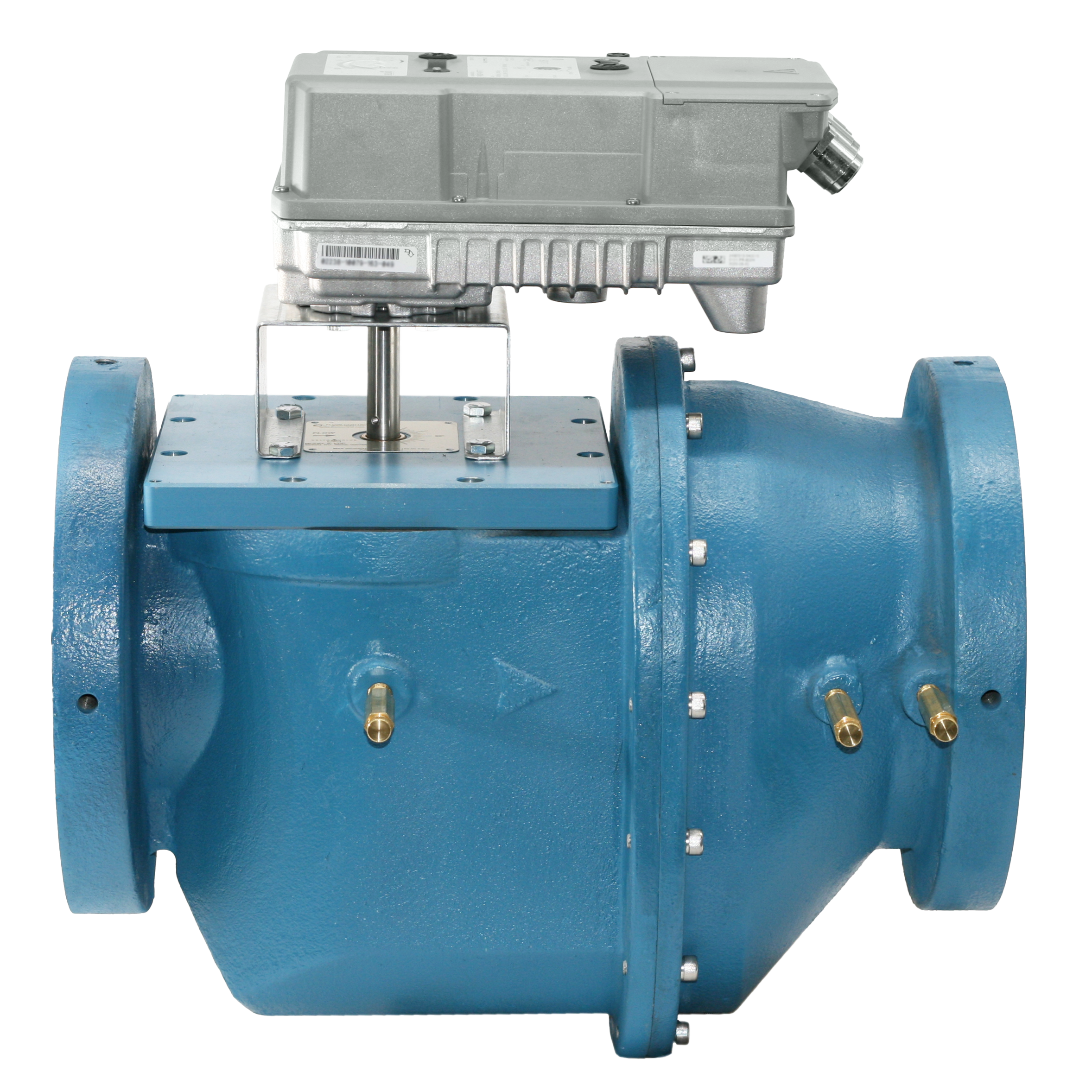

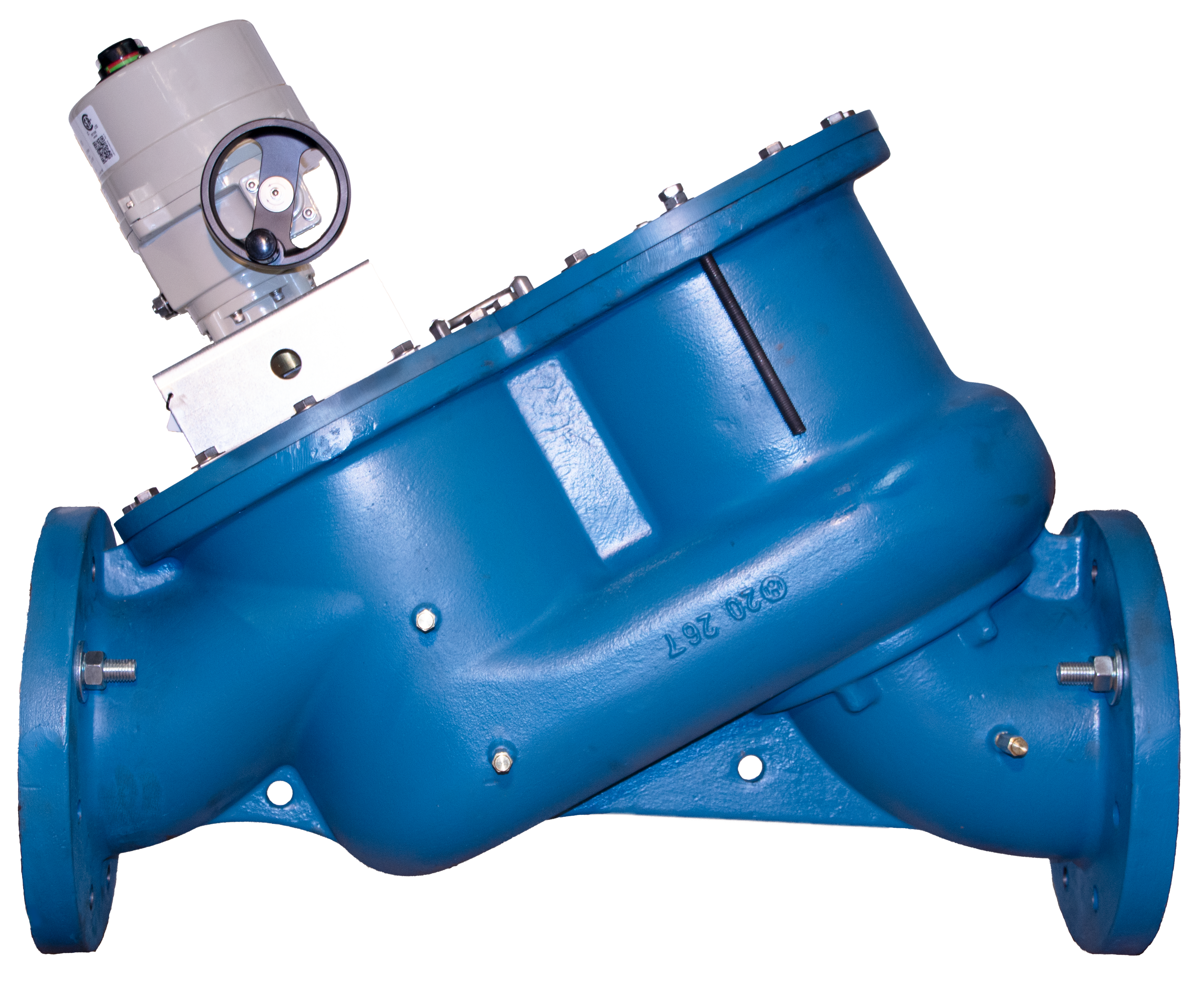

DeltaPValve®

Control Surface

Reference Pressure (P1)

Pressure Regulator

Outlet (P3)

Intermediate Pressure (P2)

Flow Path

Inlet (P1)